分离式热管低温余热有机工质蒸发器性能分析毕业论文

2020-04-15 21:41:23

摘 要

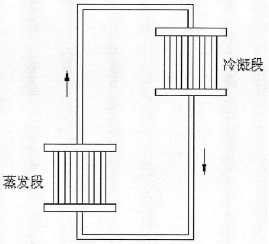

在低品位热能不断产生且绝大多数被直接排放而浪费的现状下,有机朗肯循环发电系统成为了热能再利用研究领域的重要话题,利用ORC系统回收利用低温余热烟气具有重要的意义。本文建立了双分离式热管蒸发器的设计模型,以此来进行分离式热管蒸发器相关性能的探讨分析。本文简要介绍了有机朗肯循环系统的国内外研究现状及其应用于低品位热能回收的优势,再介绍了分离式热管换热器的国内外研究现状及其优良特性,提出了使用分离式热管作为有机朗肯循环系统蒸发器所具有的优势,其既能达到有效回收低温余热的目的,又能根据需要灵活调整布置方式,以此达到节能减排的目的。

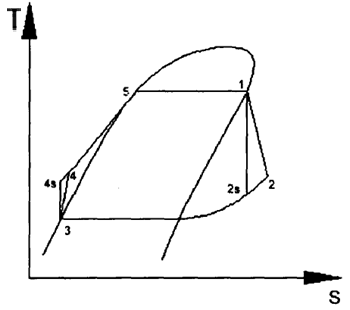

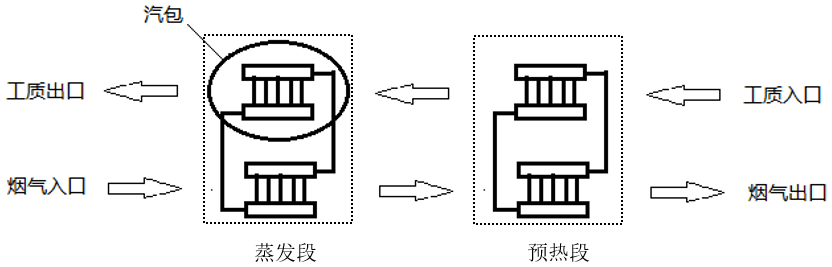

本文在分离式热管蒸发器的设计计算中,首先进行了有机朗肯循环系统的热力计算,之后提出了有机工质加热中,利用两套分离式热管分别完成预热段与等温蒸发段加热的想法,然后分别对预热段及等温蒸发段各自的蒸发端、冷凝端进行结构设计及换热计算,在计算过程中,采用了管内沸腾换热加和模型、管内凝结换热Labuntsov关联式、大容器沸腾换热库珀公式等,通过对分离式热管内蒸发端、冷凝端热阻分别进行分析计算,得出其管束传热系数,最终确定传热量及所需管数,完成其蒸发端及冷凝端管束的设计布置。最后,对分离式热管蒸发器的上升管及下降管、汽包进行了结构设计,对管内工质的充液量及充液率、传热极限、流体沿通道压降和经济效益进行了计算。

本文的初始条件:余热烟温145℃,烟气流量145000Nm3/h,烟气种类为标准烟气。在此基础上通过所设计的Excel计算程序,根据蒸发温度、窄点温差、过冷度、烟气流速、工质流速参数的修改,可自动求出其它参数。

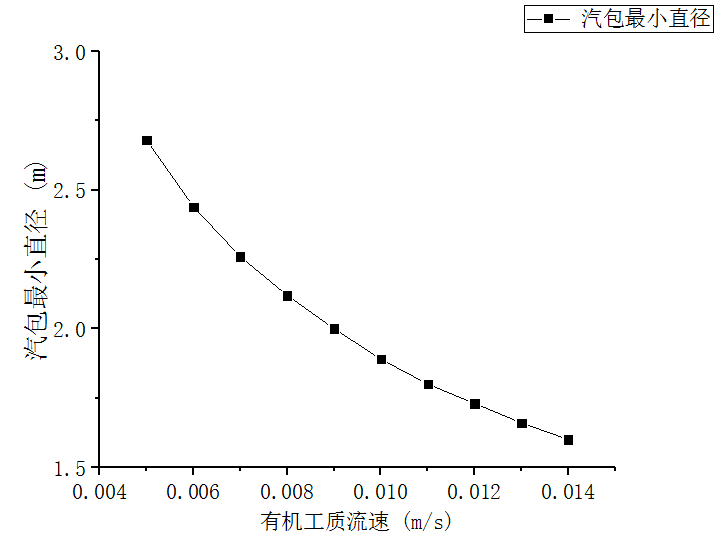

本文在结构设计及热力计算的基础上,在给定的初始条件下,利用Excel软件,进行了各参数的初步探讨分析,包括蒸发温度、窄点温差、工质流速、工质类别对汽包结构、总成本、循环净功、循环效率、年效益及成本回收周期等评价指标的影响,以求为实际工程蒸发器优化设计提供参考。

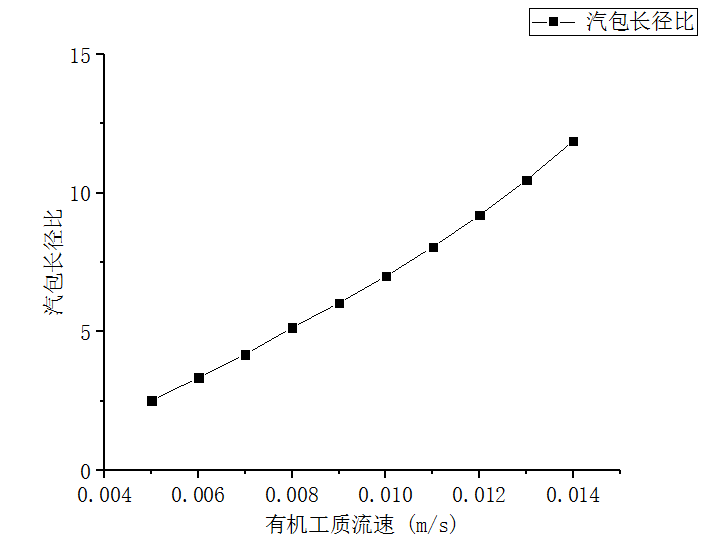

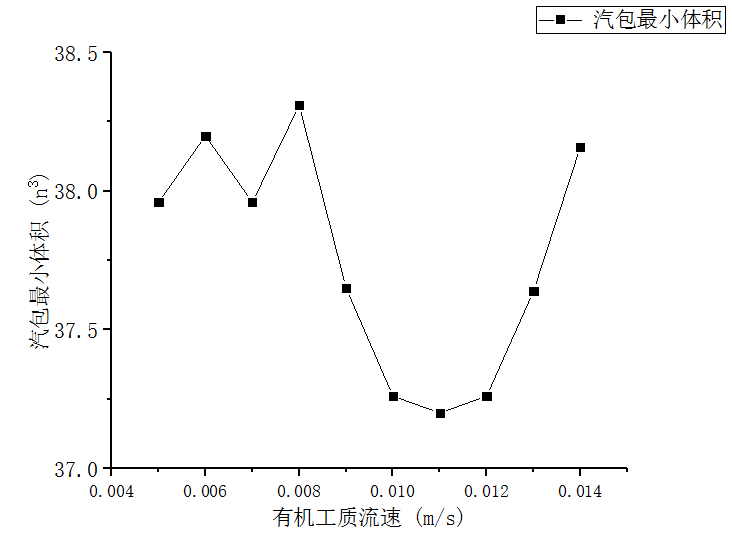

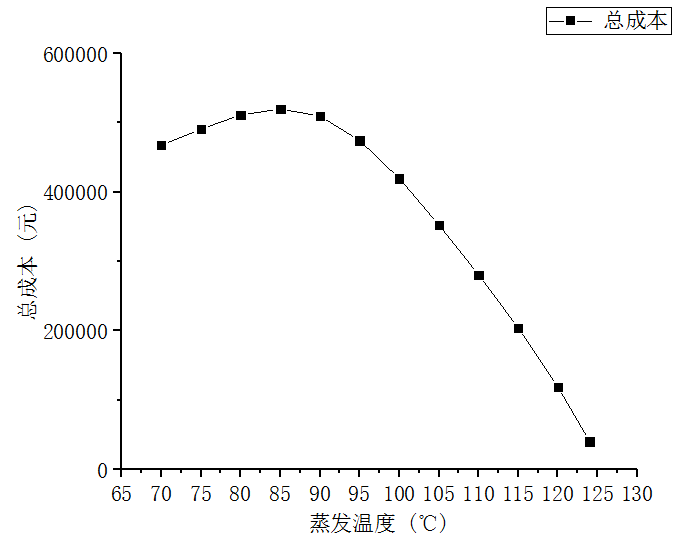

本文研究了在已知条件下,调整有机工质流量,对汽包结构设计的影响,发现有机工质流速与汽包结构设计有一定的关联性,存在最佳工质流速0.011m/s,使汽包所占空间体积达到最小值37.2m3,长径比8.06,此时,综合考虑充灌成本、占地成本及装置成本,汽包设计为最理想状态。此外,还探讨了蒸发温度及窄点温度对分离式热管蒸发器建造成本的影响,发现均存在最佳温度,使得建造周期达到最小值,当蒸发温度为115℃,窄点温差为25℃时,成本回收周期最小。最后,筛选了四种工质,R600a、R245fa、R123、R113,分别对其在相同条件下的总成本、成本回收周期、年回收效益、循环净功进行比较分析,发现R600a循环净功及年回收效益最高,R123及R113循环效率最高,R113成本回收周期最短,不同种类的有机工质在不同特性上各有优势,需对每种工质进行进一步优化分析,以达到已知条件下的最佳设计状态。

关键词:朗肯循环;蒸发器;分离式热管

Abstract

Under the situation that low quality heat energy is continuously generated and most of it is directly discharged and wasted. ORC power generation system has become an important topic in the field of thermal energy reuse research, and it is of great significance to recycle low-temperature waste heat flue gas by using ORC system. In this paper, the model of double separated heat pipe evaporator is established to discuss and analyze the performance of the separated heat pipe evaporator. Besides,the paper presents the present situation of ORC system and its application in the advantage of low quality heat energy recovery, and then it introduces the research status quo of the detached heat pipe and its excellent features. And it also considers that using the detached heat pipe as an ORC system evaporator has many advantages. For example, it can not only achieve the goal of effective recovery of low temperature waste heat, but also adjust the arrangement flexibly according to the need. And at last successfully conserve energy and reduce emissions.

In regard to the detached heat pipe evaporator design, this article has carried on the thermodynamic calculation of the ORC system firstly. Then the idea of using two sets of detached heat pipes to heat the preheating section and the evaporation section is put forward. Then the structure design and heat transfer calculation of the evaporation and condensation ends are carried out respectively. In the process of calculation, the addition model of boiling heat transfer in the tube , condensation heat transfer model Labuntsov correlations and boiling heat transfer formula for large vessels –cooper formula are used. By the method of analyzing, the heat transfer coefficient of the tube bundle was obtained, and the heat transfer and the number of tubes needed were finally determined. Finally, the structure designs of the rising pipes, falling pipes and drum of the separated heat pipe evaporator are carried out. Also, the liquid filling quantity and rate, heat transfer limit, fluid pressure drop along the channel and economic benefits were calculated.

In this paper, the initial conditions: smoke temperature 145 ℃, the flue gas flow 145000 Nm3 / h, the standard gas. On this basis, other parameters can be calculated automatically according to the modification of evaporation temperature, narrow temperature difference, supercooling degree, flow velocity of flue gas and flow velocity of working medium by the designed calculation program using Excel.

Structure design and thermal calculation is presented in this paper. And on the basis of the given initial conditions, using software of Excel, has finished the discussion about the parameters, including evaporating temperature, pinch point temperature difference, working medium flow rate, working medium category for the drum structure, the total cost, circulating net work, cycle efficiency, benefit and cost recovery period. The indexes are analized to offer usefel information for practical engineering evaporator design.

This paper studies the influence of adjusting the flow rate of organic working medium on the structure design of steam drum under the known conditions. And it finds that there is a certain correlation between the flow rate of organic working substance and the structure design of the drum. Besides the greatest working fluid flow rate is 0.011m/s, which makes the space volume of the drum reach the minimum value of 37.2m3 and the ratio of length to diameter 8.06. In addition, the influence of evaporation temperature and narrow point temperature on the construction cost of separated heat pipe evaporator is discussed. And it finds that when the evaporation temperature is 115 ℃ and the narrow point temperature difference is 25 ℃, the cost recovery cycle is the smallest. Finally, four working mediums, R600a, R245fa, R123 and R113, were selected. And their parameters with the same conditions were analyzed separately. It finds that the R600a has the highest net work and annual recovery efficiency, the R123 and R113 have the highest efficiency, and the R113 has the shortest cost recovery cycle. So different types of organic working mediums have advantages in different characteristics, and further optimization analysis should be carried out for each working medium to achieve the best design state under known conditions.

Key words: Rankine cycle; evaporator; detached Heat pipe

目 录

摘 要 I

Abstract III

第一章 绪论 1

1.1课题背景及意义 1

1.2有机朗肯循环国内外研究现状 2

1.3分离式热管国内外研究现状 2

1.4本课题的研究内容 3

第二章 ORC系统概述 4

2.1 ORC循环系统简介 4

2.2低温余热有机朗肯循环利用技术 4

2.3有机工质优选 5

2.4低温余热 ORC 发电系统的热源情况 5

2.5有机朗肯循环系统中蒸发器的作用 5

2.6本章小结 6

第三章 分离式热管换热器 7

3.1热管换热器简介 7

3.2分离式热管换热器 7

3.2.1分离式热管工作原理及应用优势 7

3.2.2分离式热管换热器的基本特性 8

3.2.3热管工质优选 9

3.3本章小结 9

第四章 分离式热管换热器结构设计及热力计算 10

4.1 ORC基本热力计算 10

4.2分离式热管蒸发器 12

4.3 分离式热管预热段蒸发端结构设计及热力计算 12

4.3.1预热段蒸发端结构设计 12

4.3.2预热段蒸发端传热计算 14

4.4 分离式热管预热段冷凝端结构设计及热力计算 17

4.4.1预热段冷凝端结构设计 17

4.4.2预热段冷凝端传热计算 18

4.5 分离式热管蒸发段蒸发端结构设计及热力计算 20

4.5.1蒸发段蒸发端结构设计 20

4.5.2蒸发段蒸发端传热计算 21

4.6 分离式热管蒸发段冷凝端结构设计及热力计算 24

4.6.1蒸发段冷凝端结构设计 24

4.6.2蒸发段冷凝端传热计算 24

4.7 分离式热管上升管及下降管结构设计 26

4.7.1预热段分离式热管上升管及下降管结构设计 26

4.7.2蒸发段分离式热管上升管及下降管结构设计 27

4.8 分离式热管汽包结构设计 27

4.9 分离式热管充液量及充液率计算 28

4.10热管传热极限计算 29

4.10.1环状膜干枯传热极限 29

4.10.2局部烧毁传热极限 29

4.10.3极限校核 29

4.11烟道及工质通道压降计算 30

4.12经济效益计算 30

4.13本章小结 31

第五章 分离式热管蒸发器性能分析 32

5.1有机工质流速对汽包结构设计的影响 32

5.2蒸发温度对成本的影响 34

5.3窄点温差对成本的影响 35

5.4不同有机工质对蒸发器性能的影响 36

5.5本章总结 37

第六章 总结与展望 37

6.1总结 38

6.2展望 39

参考文献 40

致 谢 42

第一章 绪论

1.1课题背景及意义

21世纪以来,有限的自然资源正逐渐耗尽,世人对能源合理利用提出了更高的要求。我国是发展中国家,经济的高速发展高度依赖能源,每年的能源消费量稳居世界前列,但是我国企业能源平均利用率仅为30%-40%[1],有大量工业余热被直接排放至大气中,对全球气候变暖起到不利的加速作用。众所周知,我国煤炭资源储量丰富,每年生产消耗的煤炭数量也相当可观,在我国不同种类的能源消费中,煤炭的占比可达60%-70%,其中很大一部分用于燃烧发电,导致大量燃煤余能以热能形式直接排放至空气中,除此之外,工业生产活动中燃料产生热量中的大约50%[2]也难以避免产生以低温为主的废热,因此,余热回收技术已成为能源学科的重要研究领域。

目前,针对高温余热(≥500℃)[3]及中高温余热(350℃-500℃)的科学研究已比较深入,可是低于350℃的中温,尤其对于温度低于200℃的余热,再利用效率不高且难度大,能量密度小且能量品味低,可是,若可以使用ORC循环系统进行余热发电,既能缓解我国能源紧张的现状,也能对环境保护作出贡献,所以,对于低温余热的研究任重道远。

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: