熔渣转盘离心粒化热态实验研究毕业论文

2020-07-16 20:24:41

摘 要

高炉渣是生铁冶炼过程中的主要副产物之一,其产量大而且温度高。每生产一吨钢,大约生产0.3吨高炉渣,炉渣在1400~1500℃温度范围内出炉,每吨在1500℃温度下可运输1.77GJ能量,高品质余热非常丰富。2017年我国产生约2.5亿吨的高炉渣,如将炉渣中的余热高效回收利用,据估算将近1700万吨标准煤的燃烧释放热量,可以减少约3.6吨CO2等大气污染物的排放。因此,高温炉渣余热的有效回收将对能源利用效率的提升以及建立环境友好型社会起到重要作用。目前国内外高炉渣的处理主要采用水冲急冷的湿法工艺,实践中学者们发现湿法工艺存在水耗高,同时产生大量的H2S和SOx造成空气污染工艺且没有回收熔渣的高温显热反而需后续热处理,额外消耗能源等缺点。相比之下,干法粒化中的转盘离心粒化法效率高消耗低、装置紧凑易操作、与其它余热回收设备之间的耦合使用也十分方便,应用前景十分广阔。

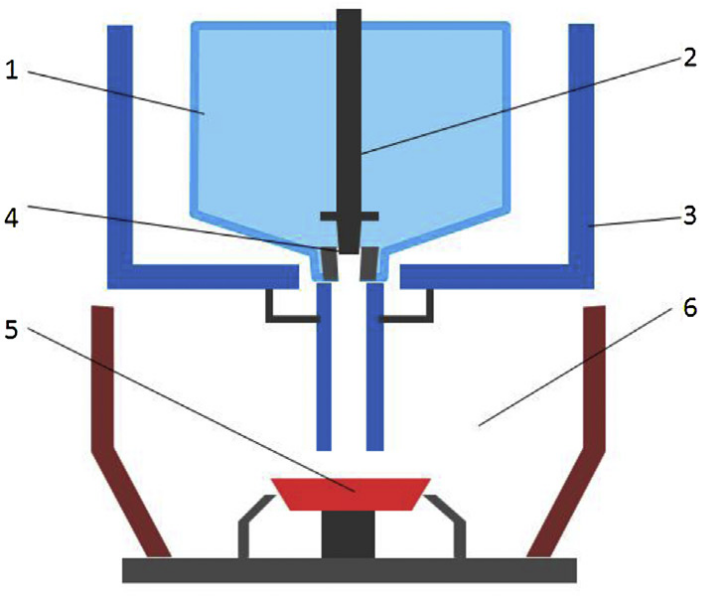

由于高炉渣导热系数较小,热阻大以及粘度随温度的降低而增大这些特点,同时存在成本的问题。故直接使用高炉渣进行离心粒化实验操作极其困难,而低温模拟实验成为研究离心造粒机理的一种简便方法。本文在离心粒化机理和相似理论的指导下,通过对离心粒化热态实验装置的探究,利用粒化收集、加热、测温装置研究了转盘转速、介质流量和转盘拓扑结构对炉渣粒化效果的影响。再经过对粒化实验数据的处理和分析,主要探明了三种典型破碎模式的形成规律;液滴平均粒径关系;液滴粒径分布;丝状物质量分数和固体颗粒均匀性规律。获得了如下结论:

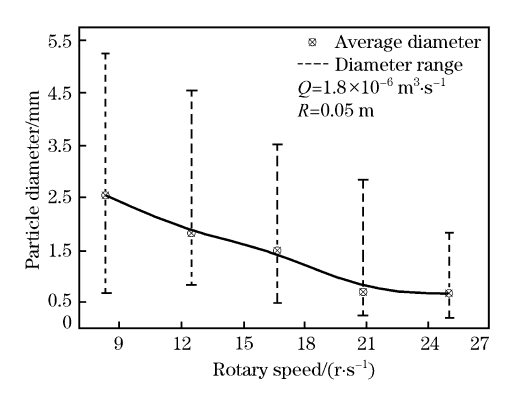

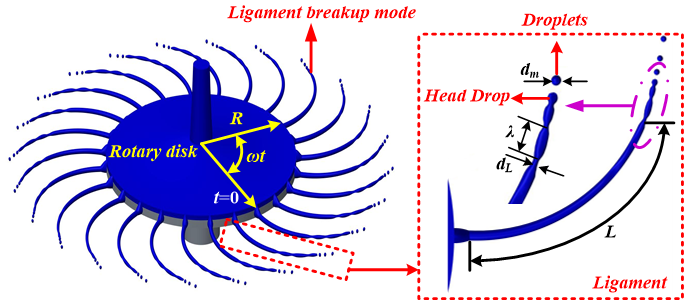

- 总体而言,液滴的平均直径(dm)随着旋转速度(ω)的增加而减小,并且当转速低于约30r/s时,平均直径减小得更快。而平均直径随着体积流量(Q)的增大略有增加。导向盘受转速的影响较小,凸台盘和弧盘由于转盘结构特点受影响较大。

- 所有转速和体积流量下的液滴尺寸均在0~8mm范围内,1~5mm范围内的液滴占质量分数的65%以上。在0~3mm范围内时,各小范围的质量分数随着转速增加而增加;3~8mm则相反。体积流率对液滴粒径分布的影响较小。导向盘和弧盘配置更有助于粒化效果的强化,产生的小液滴分布更多。

- 丝状物质量分数随体积流量值的增加或者是转速的减小而增大,其中主要受到体积流量的影响。

(4)低转速时,重力与离心力共同作用,均匀性较差。随着转速的增加,离心力、飞行距离、冷却速度等因素使获得较好均匀性颗粒。转速进一步增加,使得韧带被拉伸,颗粒均匀性又变差。平盘和弧盘与其它盘形结构相比,可以产生均匀性更好的颗粒。

通过以上研究,本实验将为拓展转盘离心粒化的应用范围提供理论支撑。

关键词:铝 盘型 平均直径 粒径分布 颗粒均匀性

ABSTRACT

Blast furnace slag is one of the main by-products in the smelting process of pig iron. Its output is large and its temperature is high.For each ton of steel produced, approximately 0.3 tons of blast furnace slag is produced.,The slag is released at a temperature range of 1400 to 1500°C.It can transport 1.77 GJ of energy per ton at a temperature of 1500°C,the high quality waste heat is very abundant.In 2017,about 2.5 million tons of blast furnace slag was produced in China.If the waste heat in the slag is efficiently recycled, it is estimated to be equal to heat from nearly 17 million tons of standard coal burned,which will reduce the emission of atmospheric pollutants such as about 3.6 tons of CO2.Therefore,the effective recovery of high-temperature slag waste heat plays an important role in the improvement of energy efficiency and the establishment of an environment-friendly society.At present,the treatment of blast furnace slag at home and abroad mainly adopts the wet process of water quenching.In practice,scholars have found that the wet process has high water consumption,and at the same time, a large number of H2S and SOx cause air pollution and the high temperature sensible heat without recovering slag needs follow-up heat treatment,additional energy dissipation and so on.In comparison,the rotary disk centrifugal granulation method in dry granulation has high efficiency,low consumption,compact and easy operation,and coupling with other waste heat recovery equipment is also very convenient,and the application prospect is very broad.

Because of the small thermal conductivity of blast furnace slag,the large heat resistance the decrease of viscosity with the decrease of temperature and the problems of cost at the same time.It is very difficult to directly use the blast furnace slag to perform centrifugal granulation experiment,and the low temperature simulation experiment is a simple way to study the centrifugal granulation mechanism.Under the guidance of the mechanism of centrifugal granulation and the similarity theory,the influence of the rotating speed of the disk,the flow of the medium and the topology of the disk on the granulating effect of the slag was studied by the investigation of the centrifugal granulation thermal experimental device.After the processing and analysis of the experimental data,the formation rules of three typical breakage modes, the average droplet diameter relation,the droplet size distribution,the mass fraction of filamentous particles and the regularity of the uniformity of solid particles are explored.The following conclusions are obtained:

(1)In general, 8the average diameter of the droplet (dm) decreases with the increase of rotation speed(ω),and the average diameter decreases faster when the speed is lower than about 30r/s.The mean diameter increased slightly with the increase of volume flow rate (Q).The slotted disk is less affected by rotation speed,the bulged-block disk and the arc plate are greatly influenced by the structural characteristics of the turntable.

(2)the droplet size under all rotational speed and volume flow is within the range of 0~8mm,and the droplets in 1~5mm range account for more than 65% of the mass fraction.In the range of 0~3mm,the mass fraction of each small area increases with the increase of rotational speed;3~8mm is the opposite.The volume flow rate has little effect on droplet size distribution.The slotted disk and arc disc configuration are more conducive to the enhancement of granulation effect and more small droplets are produced.

(3)the mass fraction of filaments increases with the increase of volume flow rate or the decrease of rotational speed, which is mainly affected by volume flow.

(4)when the speed is low,gravity and centrifugal force work together, and the uniformity is poor.With the increase of rotating speed,centrifugal force,flight distance,cooling speed and other factors make better uniform particles.The rotational speed is further increased,so that the ligament is stretched and the particle uniformity becomes worse.Compared with other disk structures, flat and arc disks can produce particles of better uniformity.

Through the above research, this experiment will provide theoretical support for expanding the application scope of centrifugal granulation of rotary table.

Key words:aluminum disk type average diameter particle size distribution particle uniformity

参数定义

dm | 平均直径 [m] | ρ | 密度 [kg/m3] | |||

m | 质量 [kg] | σ | 表面张力n [N/m] | |||

Q | 体积流率 [mL/s] | μ | 动力粘度 [Pa·s] | |||

QR | 无量纲体积流率 | λ | 毛细波长 [m] | |||

R | 转盘半径 [m] | τ | 时间 [s] | |||

Re | 雷诺数 | 下标 | ||||

T | 温度 [ºC] | L | 韧带 | |||

We | 韦伯数r | l | 液体 | |||

希腊符号 | m | 平均数 | ||||

ω | 转速 [rad/s] | |||||

目录

摘要 I

相关图片展示: