基于PLC的木塑生产设备温度解耦控制系统设计毕业论文

2020-04-12 08:59:43

摘 要

Abstract II

第1章 绪论 1

1.1 研究的背景和意义 1

1.2 木塑生产设备的发展前景 1

1.3本文研究内容 3

第2章 木塑生产设备温度解耦控制系统概述 4

2.1 木塑生产设备基本结构 4

2.2料筒加热区结构 4

2.3木塑生产设备温度解耦控制总体控制方案 5

2.4 本章小结 7

第3章 木塑温度解耦控制的控制系统硬件设计 8

3.1汇川H2U-4AM PLC 8

3.2温度传感器选型 8

3.3触摸屏 10

3.4本章小结 10

第4章 木塑温度解耦控制的控制系统软件设计 11

4.1主程序设计 11

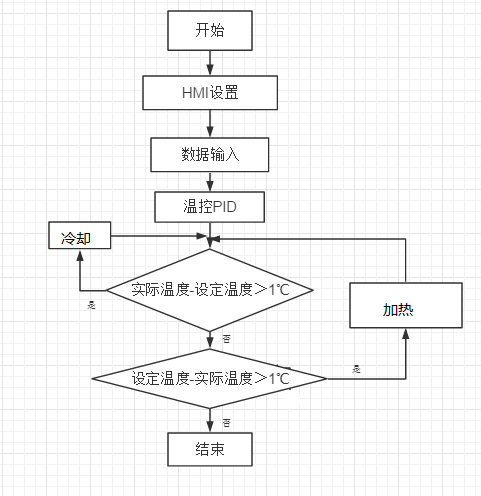

4.2温度控制子程序 11

4.3触摸屏设置子程序 12

4.4本章小结 13

第5章 木塑温度解耦控制的控制系统实现 14

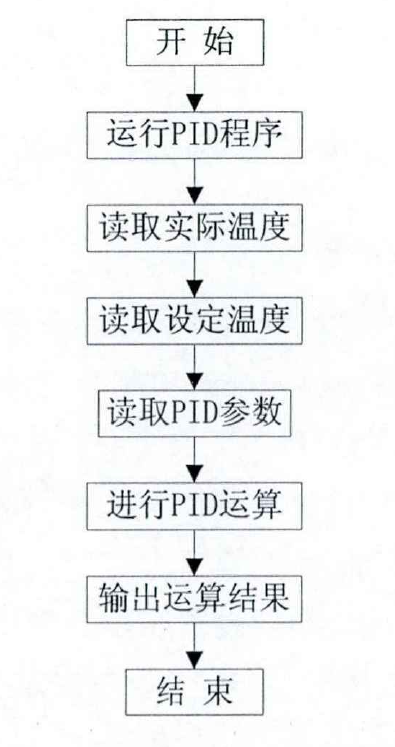

5.1 PID控制原理 14

5.1.1 PID控制器原理 14

5.1.2 PID算法实现 15

5.2多变量解耦控制算法实现 16

5.3本章小结 17

第6章 PLC程序设计及系统仿真 18

6.1 PLC程序设计 18

6.2 HMI界面设计 22

6.3系统仿真与结果分析 24

第7章 总结 26

参考文献 27

附录1 PLC程序 28

附录2 CAD图纸 31

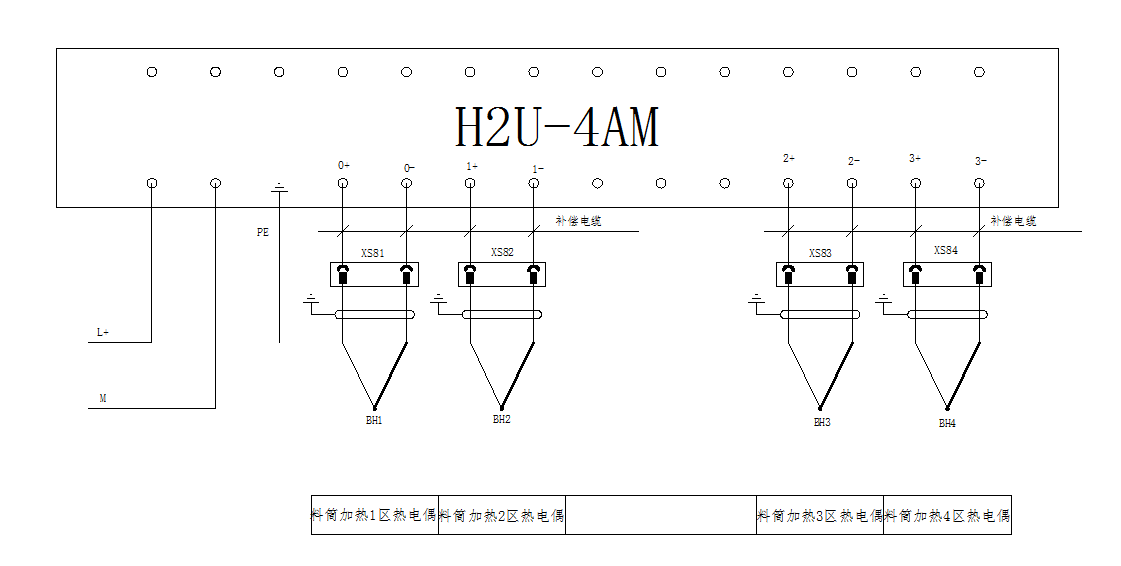

1.热电偶接线图 31

2.系统结构图 32

致 谢 34

摘 要

木塑复合材料是表示那些用塑料或无用的生物质木料为主要材料,采用高分子化学技术和塑料能够改性的特点,将某一比例的塑料木料,经标准流程加工和规范处理的,一种可再回收和再次使用的特殊材料。木塑材料的最大优点是具有基础和合成材料的多重优势。它有五大特点:1.原料资源; 2.产品的塑化; 3.环保应用;4.经济成本 ;5.回收再生。木塑材料生产设备是通过特殊工艺,生产这种新型材料的设备。

温度控制过程是木塑材料生产过程中的关键的步骤。木塑材料的质量是由受生产过程中机筒温度与机头温度所决定的。机筒一般可以分为4到7个温度区。每个区域的温度设置值可能不同,机头可分为3至5个温度区域。生产过程中机筒温度对木塑材料的混合和塑化效果拥有关键性的影响。随着料筒温度的上升,木塑复合材料熔体的表面粘度下降。对于材料的生产过程,增加温度有助于提高原材料的流动性。如果生产设备的温度设定得较高,则温度上升会引起木质纤维焦化,引起粘度过低从而不能产生满足条件的压力。木塑生产设备的高温还会使材料的粘度下降,从而影响冷却成型。产品表面焊痕的出现使产品表面粗糙,强度差,并且挤出质量受到影响,并且横截面上挤出物的热历史不均匀。由于熔体的弹性恢复的特性,出口模具呈现波浪状,并降低成品的形状性能。材料不形成经常发生,导致不连续的生产。所以,在以材料的塑化质量不受影响的基础上,应该尽量的减小生产设备的温度

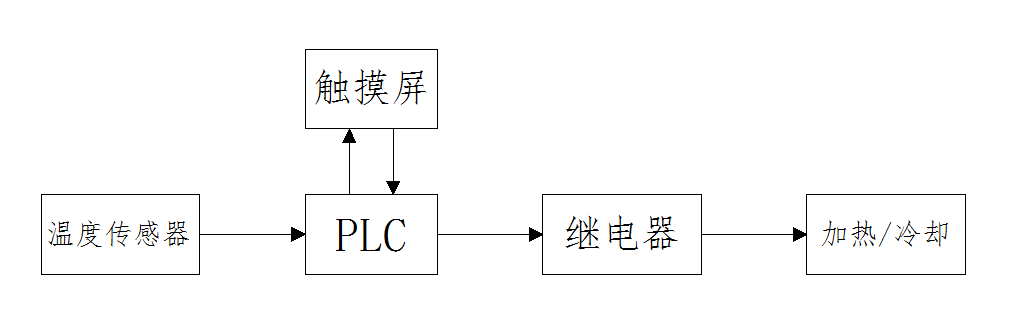

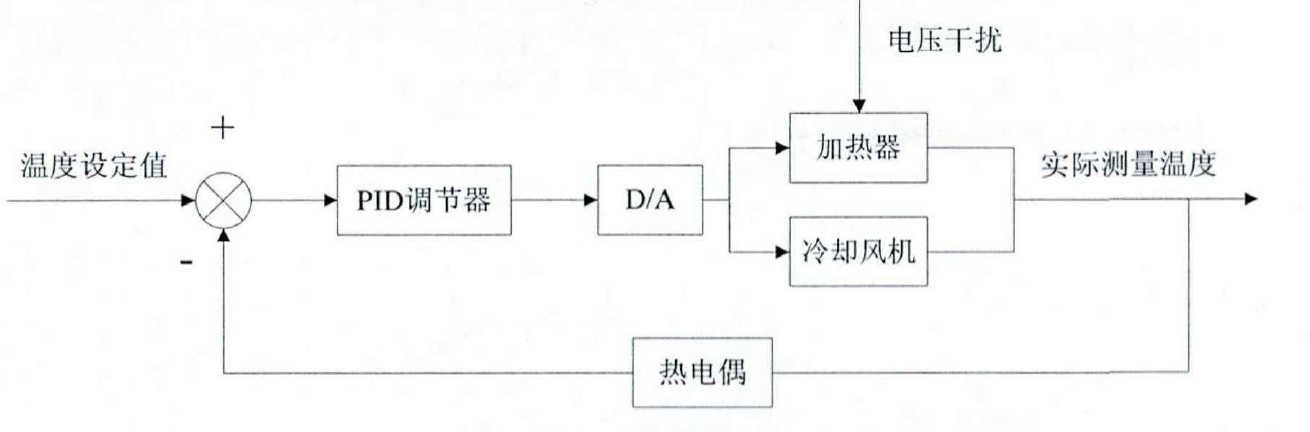

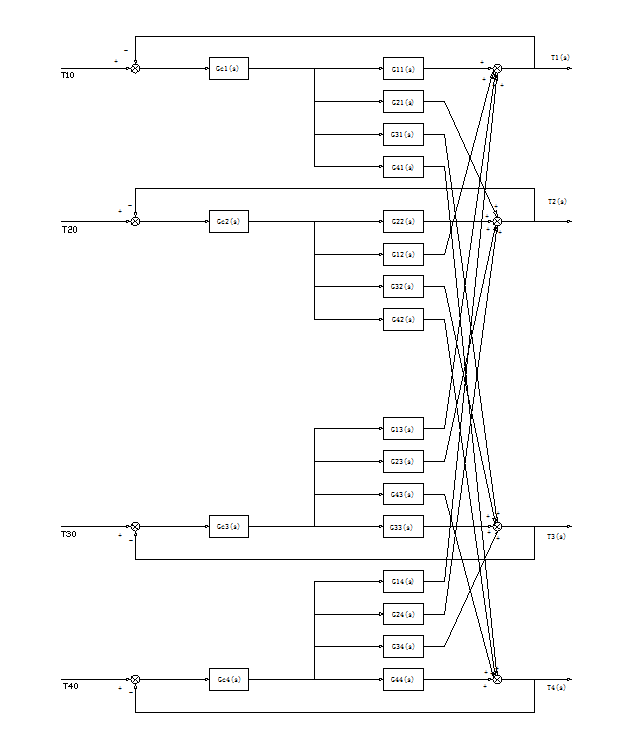

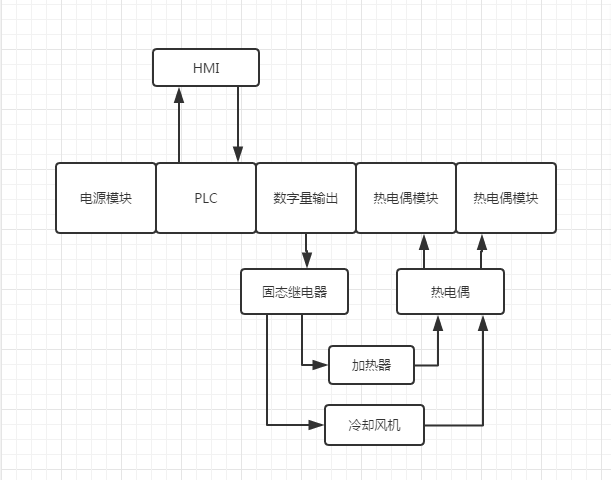

本论文主要针对的是料筒内加热区区间内多点间温度相互耦合,设计基于PLC的多点温度解耦控制系统。在实际生产过程中,料筒加热区内各个温度区都是相邻的,故每个温度区温度的变化都会引起相邻温度区温度的变化,所以应该采取多变量解耦控制。为了解决各个加热区参数强耦合的问题,本文采用多变量解耦控制来完成对加热区温度的调控。在构建温度控制系统过程中,可以运用解耦控制的技术,须要建立系统的数学化结构模型进行理论分析,然后设计控制器,最后还需考虑实际硬件设备情况从而使实现设计达到期望的控制效果。可以运用基于PLC(可编程控制器)和固态继电器的配合控制手段作为木塑温度解耦控制系统中的控制手段。

关键词:木塑材料 温度解耦控制 PLC

Abstract

Wood plastic composite is a new type of recycled material, which is made of low value or discarded biomass material, with the characteristics of polymer interface chemical principle and plastic filling modification, mixed with a certain proportion of plastic base, and processed by professional process. The biggest characteristic of wood plastic material is that it has the multiple advantages of both natural wood and synthetic plastic two different basic materials. It has five characteristics: 1, raw material resources; 2, product plasticizing; 3, application environmental protection; 4, cost economy; 5, reclaim rebiochemistry. The production equipment of wood plastic composite material is the new equipment that is produced by the integration and innovation.

The key step is to produce wood plastic materials and temperature control technology. In the extrusion process, wood plastic composites are mainly affected by the barrel temperature and the head temperature. The barrel is generally divided into 4~7 temperature zones. The temperature setting values of each partition can vary, and the nose can be divided into 3~5 temperature zones. The barrel temperature has a decisive effect on the mixing and plasticizing effect of composite materials. The head temperature has an important influence on extrusion molding. With the increase of barrel temperature, the apparent viscosity of the composite decreased. For the extrusion processing of materials, increasing the temperature helps to increase the fluidity. If the temperature of the extruder is set higher, the temperature rises to cause the burning of the wood fiber, which causes the viscosity to be too low and can not produce enough head pressure. The extruder's temperature is high, the viscosity of the material is reduced, the cooling setting is not favorable, and the surface of the product is easy to make the surface of the product. The appearance of weld marks makes the surface of the product rough, the strength is poor, and the extrusion quality is affected, and the extrusion process is uneven on the cross section. The wave shape appears after the exit mold due to the elastic recovery of the melt, which affects the appearance quality of the products. The phenomenon of unshaped materials often occurs, resulting in discontinuity in production. Therefore, on the basis of satisfying the plasticizing quality of materials, the temperature of extruders should be reduced as far as possible.

This paper is mainly aimed at the temperature coupling between multi points in the heating zone of the barrel, and designs a multi-point temperature decoupling control system based on PLC. In the actual production process, each temperature zone in the heating zone of the barrel is adjacent, so the temperature change in each temperature zone will cause the change of the temperature in the adjacent temperature zone, so the multivariable decoupling control must be adopted. In order to solve the problem of strong coupling between various heating zones, a multivariable adaptive decoupling control is adopted to control the temperature in the heating zone. In the process of building the temperature control system, the method of decoupling control should be adopted, the mathematical model of the system needs to be established, and then the controller is designed. Finally, the actual hardware equipment is also needed to make the design achieve the desired control effect. The control method based on PLC (programmable logic controller) and frequency converter can be used as the control method in the wood plastic temperature decoupling control system.

Key words: wood plastic;temperature decoupling control;PLC

第1章 绪论

1.1 研究的背景和意义

随着科学技术的不断进步和环保观念逐渐深入人心,材料与材料的混合复配是新型材料领域发展的必经过程,复合材料也是如此。从上个世纪80年代开始,木塑材料开始进行产业化生产,美国是主要起源地之一。最早的木塑复合材料都是被用来当做改性塑料来使用。但由于木塑材料的生产水准的进步与创新,这些有关制造物也慢慢拥有了例如塑料、金属木头、等某些单一质材各种长处,木塑材料逐渐体现出其的产品特性,慢慢的形成了一种拥有独立系统的新型材料。木塑材料展现的优良特性不单单十分符合建造行业、物流行业、装饰行业等范畴的性能要求,并且还解决了旧塑料废弃物、木材行业,乃至农业方面废弃木质材料的可持续发展问题,这大大推进和促进了木塑复合材料的研发进度,让它慢慢的成为一种新的优质材料。如今中国境内的木塑材料专用生产设备的制造厂家并不多,但他们的影响和作用正在慢慢增大。和那些成熟的塑料加工的机器行业相比,虽然有越来越多的公司想要进入木塑生产设备的生产行列中来,然而因为受到木塑材料的科学技术水平的约束,还有对木塑加工工艺过程理解不够,达到想要的目的仍存在不少难题。并且,不少的木塑生产设备的制造公司在还发展中碰到科技人才、资金、公司规模等条件的约束,他们的发展也不是一帆风顺的。与此同时,还要必须了解到的其他事实是境外的某些木塑生产设备生产制造公司,例如:美国的Davis Denton企业、TK pars企业、Mirakron Cincinnati企业等一直想要占领中国巨大的木塑复合材料市场。假如国家不在这个方面有正确的政策和对应的措施帮助自己的企业,那么那些在国内生产行业中少量能够与西方国家相竞争的刚成立的木塑制造行业将会承受不小的打压。

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: